The production process of any publication, including a book, catalogue, or album, involves not only printing individual pages and preparing an aesthetic and attractive cover for the reader, but also applying the appropriate book block binding technology.

The printing industry most commonly uses two techniques: sewing or gluing. How do they differ?

Sewn and glued blocks – a comparison of both technologies

Binding blocks using the gluing method

This method involves the precise gluing of pages whose spine has been processed using a milling technique. This process aims to even out its surface and expose the paper fibres, which is necessary to increase the binding strength within the block. The embedding of individual fibres translates to a higher stability of the book, even with intensive use. Glue binding a book block is one of the most common methods used in the printing market.

Binding blocks using the sewing method

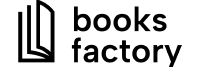

How is a book block bound using the sewing method? This procedure involves gluing together signatures (sections) that have been sewn into gatherings. Each of these is a multiple of 4 pages. In practice, this means each gathering contains 16, 20, or even 24 pages, which increases the block’s durability and its ability to open fully without risk of damaging the publication. This method is used especially when there is a need to achieve maximum lay-flat ability, which is primarily desired for manuals, musical scores, and liturgical books.

Gluing and sewing blocks – advantages and disadvantages

Sewing book blocks

Book binding by sewing is one of the oldest methods, practised in the Middle Ages and even earlier. It involves joining individual signatures together using thread. Thanks to this, the block gains durability and strength, and its ease of opening is also increased. This last feature is very important, as it allows the block to lie flat when opened, which significantly facilitates reading and viewing illustrations within the publication (even large-format ones). Another advantage of the sewing method is its prestige, as it is considered more exclusive in the bookbinding industry.

The disadvantages of sewing book blocks include, among others, higher production costs and a longer turnaround time, which result from the need to implement additional technological steps.

The block sewing method is particularly suitable for publications that will be used for a much longer time and thus must be distinguished by durability and reliability. It is especially recommended for scientific and academic books, albums, luxury and limited-edition publications, as well as encyclopaedias, dictionaries, and other books of relatively high value and volume.

Gluing book blocks

There are two methods of binding books using adhesive. They differ in the type of material used, which can be:

- polyurethane adhesive (PUR), characterised by an exceptionally strong and durable bond, thanks to the chemical reaction that occurs during binding. PUR binding is also resistant to moisture and extreme temperatures, making the books more durable,

- EVA adhesive, which is a so-called hot-melt adhesive that melts under high temperature and hardens as it cools. This is a faster and more economical method, but its durability and resistance to external factors are lower compared to PUR adhesive.

Glue binding a book block has a number of advantages. Firstly, it is a method that generates low production costs, as it is cheaper than sewing a book. Secondly, using glue is faster and technologically simpler, allowing the printing house to minimise the turnaround time for even very large print runs. Another advantage of glued books is their even, smooth spine, which makes the publications look modern and professional.

The disadvantages of gluing include lower durability of the block, especially if it is subjected to intensive use. A certain limitation is also the reduced lay-flat ability, meaning the publication does not open as flat as books bound using the sewing method.

The gluing method is used primarily for fiction books and manuals, as well as catalogues and company reports. It is also commonly used for binding magazines and periodicals, as well as for books released in medium and large print runs, where a favourable unit price plays a particular role.

Which block binding method do we recommend at Books Factory?

The choice of block binding method depends on a number of factors. By choosing Books Factory’s offer, you can be sure that every technique we use is fully professional, ensuring your publication will be exactly as you expect.

When choosing a block binding method, be sure to consider:

- the book’s purpose – luxury publications are worth sewing, while glued bindings are better for fiction,

- the book’s print run – for large print runs, gluing is a more cost-effective solution, as this process generates lower costs,

- format and volume – the thicker and heavier the book, the more advisable sewing becomes,

- types of book covers – for softcovers, glue binding the block is a better solution; conversely, hardcover, exclusive covers are worth sewing.

In summary, the choice between sewing and gluing a book block is a compromise between cost, durability, and aesthetics. Sewing provides the highest durability and a prestigious character, but it involves greater financial outlay and a longer production time. Gluing, on the other hand, is fast, economical, and ideal for most popular publications, especially those of medium volume and a shorter life cycle.

Order Sample Books and see for yourself the durability of sewing and PUR gluing. Contact us and request a free copy.